Drilling through 1600 meters: China's drilling tools win the global energy drilling stage

03 Nov 2025

section339 original, welcome to read.

In September 2025, in the vast Gudamis basin in Algeria, North Africa, a geocentric1600 the march into the depths of the meter is quietly becoming a stage to show the hard core strength of China's high-end drilling tools.

As a pioneer in shale gas development in Africa, Algeria's national oil company, its procurement department, through rigorous data traceability six months ago, finally targeted the company and signed a1600 mi oil shale deep well drilling tool supply contract.

This is not only the landing of a single order, but also a vivid epitome of China's drilling tool industry from "following" to "running side by side" and even "leading" in specific fields,

it indicates that the strategy of "drilling tool power" is bursting with dazzling competitiveness in the cutting-edge arena of global ultra-deep wells.

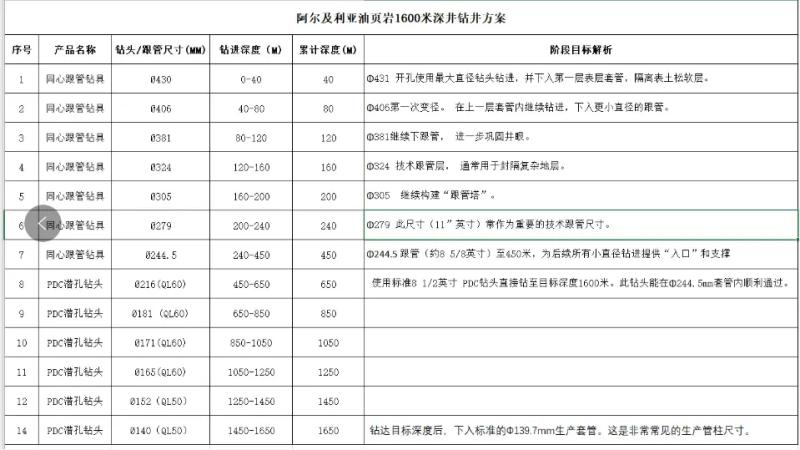

first, the oil shale deep well project construction plan (mining well) detailed sharing as follows,

phase I: Surface and technical CASING DRILLING (the goal is to provide safe passage for deep drilling)

1 Φ431, 0 - 40 m open the hole and run the surface casing. Isolate the loose surface layer to prevent collapse.

2 Φ406, 40 - 80 m lower the second sleeve. Further consolidate the upper wellbore.

3 Φ381, 80 - 120 m continue to build the wellbore structure.

4 Φ324,120-160 m the lower technical casing seals off possible shallow water or unstable formations.

5 Φ305,160-200 m continue to lower the technical casing.

6 Φ279,200-240 m this size is often used as an important technical casing.

7 Φ244.5 240 - 450 m 450 the Φ of the customer's original plan219 casing upgrade to Φ244.5mm sleeve. This is the standard9 5/8 inch technical casing provides more space for subsequent running into thicker production strings.

Stage 2: Production Hole Drilling

PDC the down-the-hole full drill drills drill through the target oil shale layer and then run into the production casing or screen.

Φ215.9450 meters -1600 meters using standard 8 1/2 inch PDC full drill (drill directly to target depth1600 meters.

This drill bit can be used in Φ244.5mm the casing is smoothly passed through and a hole of regular size is drilled. After reaching the target depth, run the standard Φ139.7mm production casing. This is a very common production string size.

II. Drilling Tools Technology in China "Hard core" strength, from "available" to "easy to use" technology leap:

in the Algerian project plan, two key optimization points accurately reflect the evolution of Chinese manufacturing,

1. Proactive Design: From "apply standards" to "custom optimization".

The original scheme of Φ219 casing upgrade to Φ244.5mm standard technology bushings are by no means simple dimensional changes.

Behind this is a team of outstanding Chinese engineers represented by Xie Linhui from Hunan Jie Diamond Company, who have a deep understanding and flexible application of different oilfield standard systems around the world.

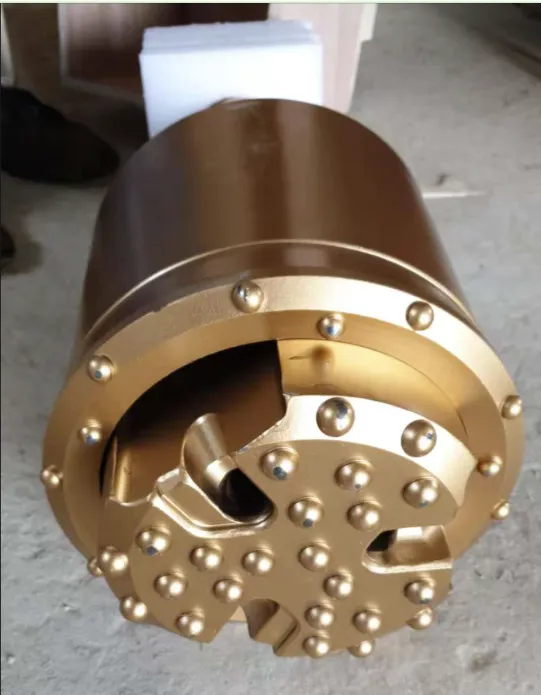

Will be concentric with the pipe drilling tool, PDC introduction of high wind pressure DTH bit global Energy in the field of ultra-deep wells, this is a bold attempt and an amazing pioneering work!

It is estimated that the total cost of a production well is 300. Million dollars-500 million dollars. Concentric heel pipe drilling tools used in 1600 meters, PDC the high wind pressure down-the-hole drill bit is only" nine Niu YiMao ", it must be a big order for us drill tool exporters.

Test data by customer: Polaroid high quality drilling tools the drilling cycle is shortened by 60%, and a single well can save 40-500000 US dollars in investment.

2. Systematic matching: from "single point of breakthrough" to "Overall Excellence".

Use Φ215.9mm(8-1/2 inches) full drill bit drills through the production layer and perfectly matches the upper casing, which reflects the completeness and systematicness of China's drilling tool "toolkit.

This means that what China provides is no longer a single drill bit or casing, but a set of "drilling tool ecosystem" that has been precisely calculated and verified in actual combat, ensuring that the entire process from opening to completion is efficient, stable and reliable.

Third, the "deep well" Arena: why can Chinese drilling tools win the world?

Ultra-deep well drilling is the field with the highest technical density and the greatest challenge in deep shale oil and gas engineering, and is known as "mobile Space Engineering". Its test for Chinese drilling tools is all-round the core is material process.

In this "Deep Well" competition, practice and response in recent years, the state proposed" strong material base, tool industry" country strategy and global layout.

1. Materials science under extreme conditions:

underground1600 high temperature, high pressure, high corrosion and hard abrasive formation. The breakthrough of basic material technology such as brazing steel, hard alloy and superhard composite materials in China and the deep integration of ecology are the foundation for drilling tools to "gnaw" hard bones, maintain high speed and long life.

2. Precision manufacturing process:

the strength of each point of the drilling tool and the tooth angle of each cutting tooth directly affect the success or failure of the whole drilling operation.

The transformation and upgrading of China's manufacturing industry as a whole has provided key process guarantees such as precision machining and heat treatment for drilling tools. The successful advancement of the Algerian project is proof that Chinese drilling tools have passed these rigorous tests.

It declares to the world that in the "deep Land" strategy of competing for future energy, China has mastered an indispensable "land entry" weapon.

The practice of Baoruide in deep wells of Algerian oil shale is a precise aspect of the rise of China's drilling power.

When China's drill bit goes deep into the belly, when China's casing builds an energy channel, what we see is not only the completion of a multi-million dollar well, but also the climbing of an industry in the global value chain.

It can be felt that in the future, sales of drilling tools and export drilling tools can no longer be priced or rolled up. As "iron bumps", sell materials, sell products.

This is 2025 dominated by national power." hard alloy sheet intrinsic price increase logic". Product + Technology + service of high-end drilling tool export, it is the upper level that forces the domestic drill industry to make clear the signal and purpose.

The foundation of "drilling tool power" lies in "drilling tool industry power".

Building a "drill industrial power" is not an unattainable goal, it is by again and again. China tungsten Industry take off, time and time again the carbide industry upgrades, new material research and development,

every piece of excellence drilling products offline, every successful international cooperation, each by the global market recognized by the technical standards cast.

This mouth1600 the deep well is a solid step for China's drilling tool industry to move towards the high end of the global value chain.

With technology as the blade and standards as the shield, Chinese drilling tools are carving "Chinese depth" for global energy drilling ".

On this journey to the center of the Earth, Chinese drilling tools are drilling a new world with their unstoppable spirit.