How can China rock drilling tools supplier facing the challenge of Tungsten Carbide rising prices

11 Sep 2025

Today is the last day of August. There's no need to look back and count the regrets, after all, the end of summer has always been accompanied by a gentle sense of ritual.

Undoubtedly, rivaling the heat of the 2025 summer is the enthusiastic surge in domestic cemented carbide. In August, every time we inquired about prices from drill tool factories, their catchphrase was: "Drill bit quotes are valid for three days.

Previously, drill tool factories were desperately clamoring for orders. Now, faced with the successive price increases of upstream cemented carbide, they turn pale at the mention of prices. They are extremely distressed when there are no orders and jumpy with anxiety when there are orders. Looking at the overall situation of domestic drill tool factories in August, it can be said that they are "happy yet painful.

Recently, the price of cemented carbide has surged again (tungsten carbide has increased by 16.78% year-on-year), which has severely weakened the price competitive advantage of China's drilling tool manufacturers and foreign trade enterprises. This has led to a dilemma of "taking orders means losses, while abandoning orders means losing the market", with the export of low and medium-end products being particularly severely impacted.

Last month, a notice on price increases in Zhejiang's drilling tools market was issued. Several powerful factories in Hunan have shown their "diamond-like character" by temporarily not raising the prices of high-pressure DTH drilling tools, but the "overwhelming pressure" is evident without words.

The situation of the general manager of a DTH drill production enterprise in Hunan is very typical. He told me that he was very happy to receive an export order for 5,000 low-air-pressure DTH drills of Cir90-95mm, but he dared not accept the order due to high costs, falling into the dilemma of "if I don't accept it, the customer will leave; if I accept it, I will lose money".

This situation is not uncommon among current drilling tool export enterprises. As a drilling tool exporter, I have personal experience, feelings to express, and evidence to write about.

Sudibeng Iro Ore iron mining area is a relatively well-known mining area in South Africa. It has been using ProDrill DTH bits. If we think of the bits as wine, they must be considered vintage wines. In recent months, the demand for DTH bits has been several hundred per month, and the sharp rise in the price of cemented carbide has become an unbearable burden for customers.

For export-oriented drilling tool enterprises, the increase in costs has weakened their advantages in international quotations. Some customers have frankly stated that they are now purchasing DTH bits from factories in India and Eastern Europe to replace Chinese bit products.

After decades of development, China's cemented carbide industry has transformed from relying on imports to becoming a major global producer and consumer. As of 2024, cemented carbide accounts for 63% of China's tungsten consumption structure, with an annual usage of approximately 40,300 tons, of which mining drill bits account for 15% of the total usage.

China's cemented carbide industry has approached the international advanced level. In addition to meeting the needs of the domestic mining industry, it is actively entering the global market.

The sharp rise in the price of cemented carbide has had multi-faceted impacts on the operations of drill tool manufacturers and foreign trade companies, posing unprecedented challenges.

A significant rise in production costs: Cemented carbide, known as the "teeth of industry," is the core material for rock drilling bits and accounts for a high proportion of product costs. Take synthetic diamond production as an example: cemented carbide top hammers account for more than 40% of the total production cost of diamonds.

Similarly, in the production of drilling tools, cemented carbide is also a major component of costs. The significant price increase has directly led to a surge in cost pressures for manufacturing enterprises, severely squeezing their profit margins. Some enterprises have even experienced a phenomenon where "product selling prices ar inverted with costs", which has exceeded the range that enterprises can bear in their operations.

Accelerated technological innovation and product upgrading: Under pressure, drill tool manufacturers are paying more attention to improving the technological content and added value of their products.

Some enterprises have begun to accelerate the research and development of tool use technologies and supporting equipment, helping mining enterprises establish workshops for tool regrinding and recovery of residual cemented carbide inserts, so as to improve the effective utilization rate of alloys, promote the recycling of residual alloy inserts, and build a resource-saving production system. This transformation is conducive to the long-term sustainable development of the industry, but it also requires upfront investment and equipment transformation.

For foreign trade enterprises, in the face of price increases by drill bit factories, it is inevitable to raise export prices. Originally, they only made profits from tax rebates on bulk drilling tool orders, but now the price increase has already offset the tax rebates, leaving export enterprises in a difficult situation.

On the one hand, foreign trade exporters should deeply cooperate with drilling tool manufacturers to overcome difficulties together. On the other hand, they must improve their ability to design high-quality drill bits and extend the drilling meters of the bits to create more value for customers, so as to retain existing customers.

The owner of a marble quarry in Hualien, Taiwan, purchased COPROD89-115 drill bits from Prodrill Inc. After 3-4 repeated designs, the drill bit has completed 3473.6 meters of drilling with one regrinding. Compared with the original 2500 meters and 3000 meters, the effect of the drill bit now reaching nearly 3473.6 meters is shown in the pictures below. Recently, the customer happily said that this drill bit, which has drilled nearly 3500 meters, can continue to drill. This length is even better than the original EPIROC one, which is incredible!

The skyrocketing price of cemented carbide this time marks the end of the era of low-price competition among drill bit exporters, forcing foreign trade companies to reflect on the severe and realistic issue of how to develop through cooperation with drill tool factories and survive in competition.

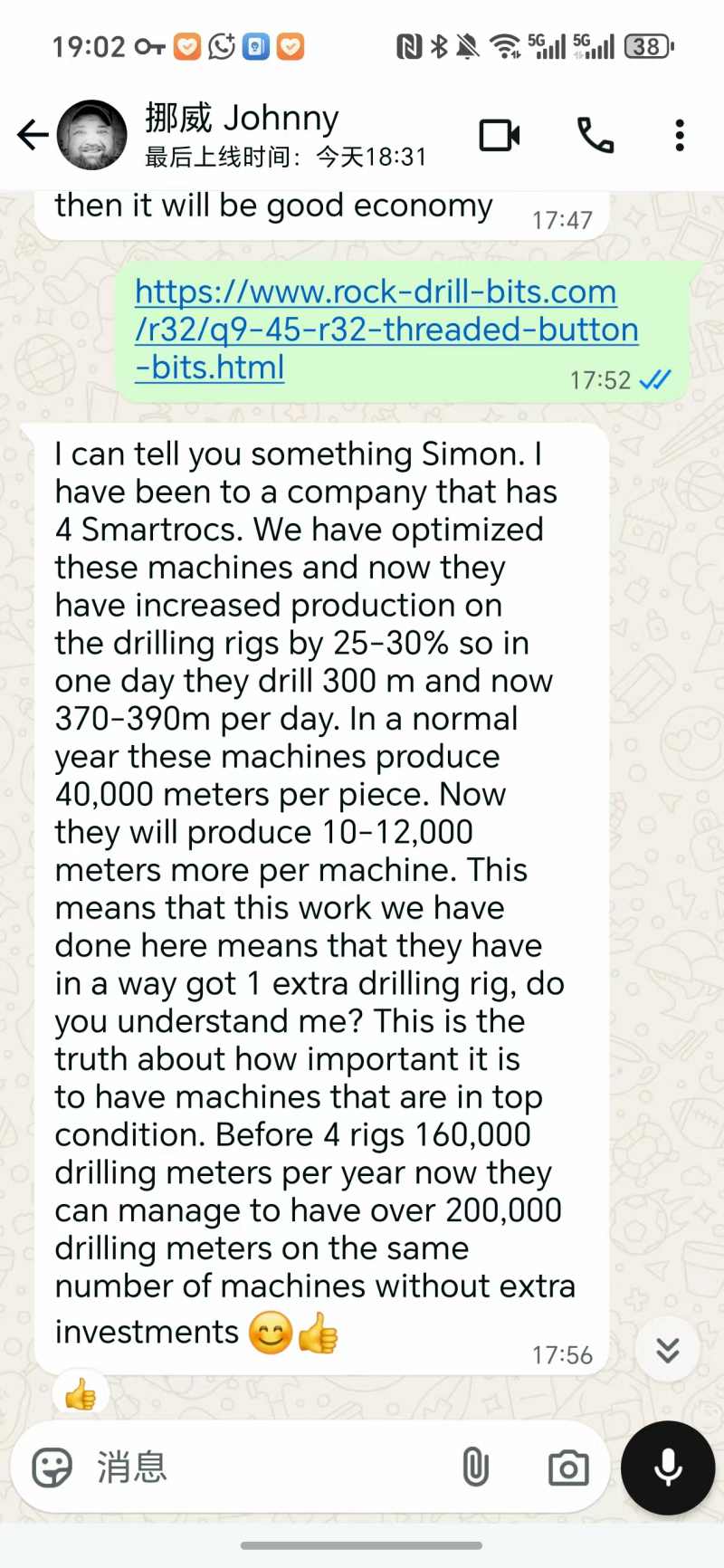

We have fully mastered the drill tool technology, improved the bit design capability, enhanced the customer service ability, strengthened customer stickiness, and successfully customized the bits. The scientific and optimized drilling design has played a crucial role. As Johnny, a senior drill tool expert in the Nordic mining industry and a Norwegian customer who has cooperated with us for many years, said:

Based on the rock system, working conditions, drilling rig configuration and customer requirements, continuously improving the bit design level and continuously optimizing the drill bit design capability are a compulsory course for every drill tool exporter. In the case of significant fluctuations in the price of drill bit factories, it is also a magic weapon for enterprises to remain invincible.

In conclusion, the sharp fluctuations in cemented carbide prices have indeed posed severe challenges to drill tool enterprises, but this is also an important opportunity for industrial transformation and upgrading. By comprehensively adopting multi-dimensional strategies such as supply chain optimization, product upgrading, market diversification, efficiency improvement, and policy utilization, enterprises can not only overcome the current difficulties but also gain a more favorable position in future market competition.

Most importantly, enterprises need to maintain strategic focus, adhere to innovation-driven development, actively adapt to market changes, convert short-term pressures into momentum for long-term development, and ultimately achieve sustainable development.

Today is the last day of August. There's no need to look back and count the regrets, after all, the end of summer has always been accompanied by a gentle sense of ritual. Leave the unspoken expectations to September, and let the new season, with new possibilities, slowly unfold in the morning light.

September is the most beautiful season. The regrets of summer will surely be gently resolved by the autumn wind. May love and good luck be with us this autumn.