Product

Hot product

Contact us

Home>Products > THREADED BUTTON BITS > T51 >

Rock Drilling Tools for Australia Mining

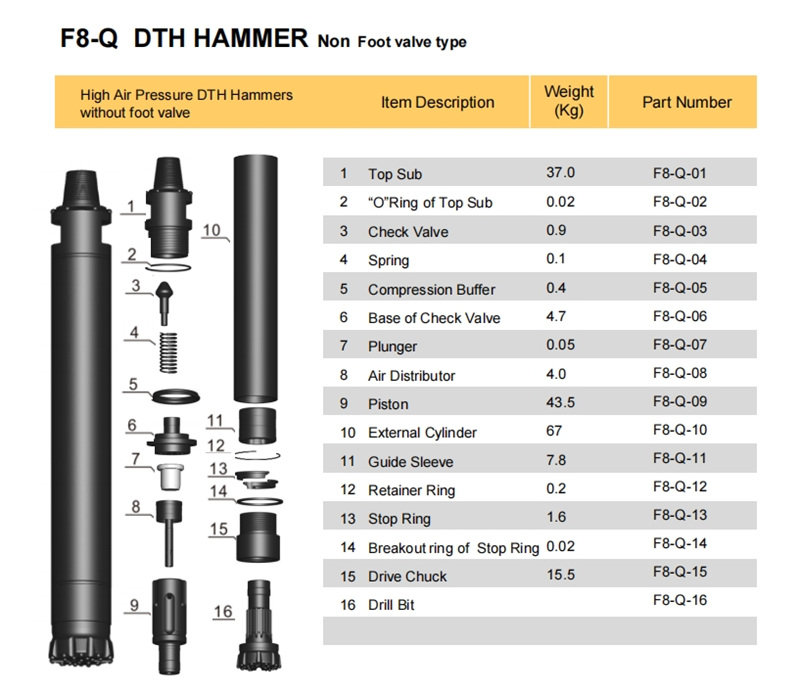

- Prodrill ™ rock tools for top hammer or down the hole drilling are designed to transmit intensive impact energy into the rock with the least possible loss of energy. The result is good rock breakage, high penetration rates and high productivity. :

- Along with optimal hole quality, great reliability, and long service life, Prodrill ™ ’s tools deliver you the best possible blasting results, outstanding drill-steel economy and low overall operating cost. :

- :